Rapid Prototype(RP) is usually done to check the feasibility of a newly developed or designed product. It can be effective in identifying defects or anomalies, which can quickly help improve the product. meanwhile, it can also be used to check whether a new product is ready for mass production and for market research. Through feedback and improvement, it provides sufficient basis for mass production and market expansion planning.

In order to support our customers to gain more competitiveness in the market , Our strategic partner is not only equipped with a variety of manufacturing and processing equipment, but also has a group of professional manual craftsman with years of practical experience. We specialized in making difficult, flexible and creative product models that cannot be completed by machining, and can quickly complete samples according to our customers’ needs, which saves a lot of your time.

Our advantages

• More than 10 years’ experience in prototype industry • Capable of making all kinds of high-precision, difficult and particularly complex prototypes.

Rapid Prototype Manufacturing Service

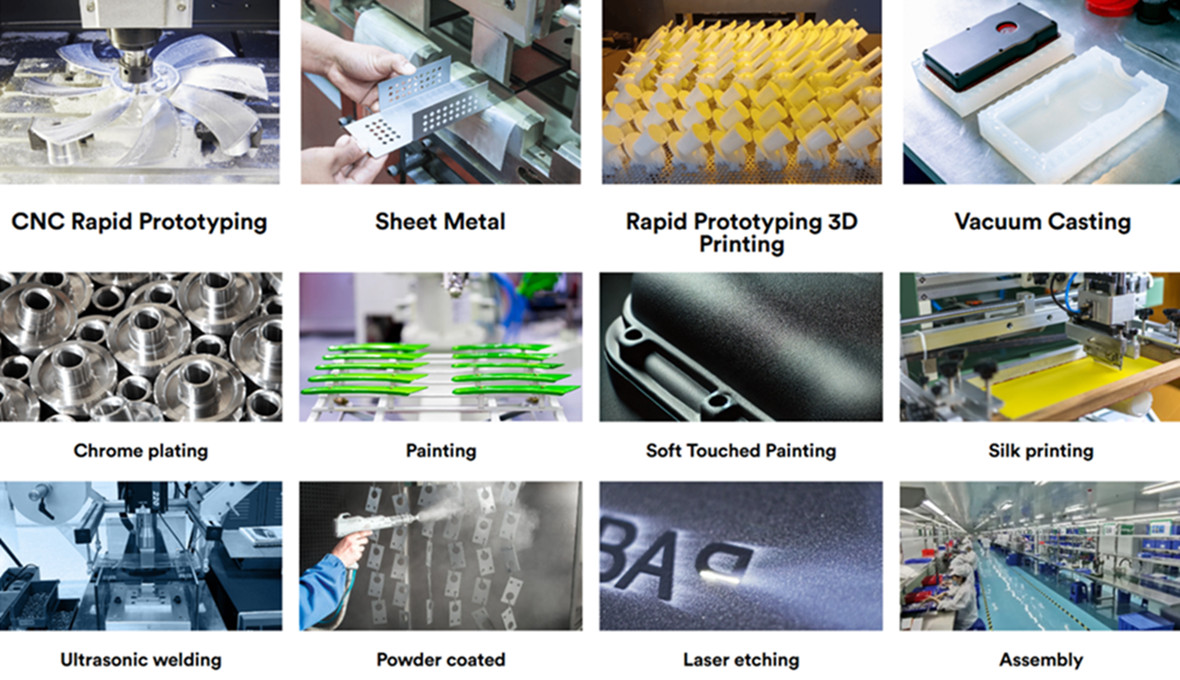

CNC Machining

Main processing methods of rapid prototype,CNC is a computerized numerical control machine equipment, which cuts a whole plate by controlling the tool path according

to the programmed program. At present, it is the most widely used machining process domestically.

The main plastic materials: ABS, PC, POM, PMMA, etc. and main metal materials: aluminum, steel, copper… and so on.

CNC milling machines aims to fabricate some irregular products and CNC lathe is used to manufacture some round parts.

CNC milling can manufacture some large parts, which is cheaper than SLA and suitable for many kinds of prototypes.

Up to 3000 × 1200× 600mm in size, accuracy +/-0.1mm Please click below for more detail of CNC.

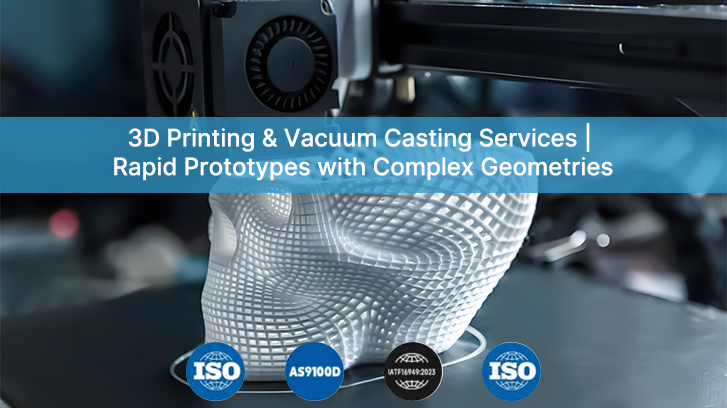

3D Printing & Machining Capabilities

3D Printing Materials ( Metals : Aluminum ,Stainless Steel ,Titanium, Inconel, Cobalt Chrome, Copper . Plastics : Nylon ABS Polyethylene Polycarbonate TPU)

3D Printing Parts Surface Finishing Options: Powder Coating/ Bead Blasting/ Polishing/ Painting

Sheet Metal Fabrication

Sheet metal is a kind of comprehensive cold processing for sheet metals , usually less than 8mm in length.

Including shearing, stamping, laser cutting, bending, welding, riveting, splicing and forming. Its remarkable feature is the same thickness in the same part,

and been widely used in products such as enclosures and covers.

Sheet metal materials: aluminum, copper, steel and other metal plates, Sure some Plastic materials can also be used for bending.

Vacuum Casting or Urethane Cating

Firstly, a silicone is made by putting the prototype in a vacuum environment in which filling it ,with polyurethane materials so the replica can be duplicated through the process.

It minimizes the risks during production and offers advantages, like high efficiency and low cost.

• Closed silicone mold—Vacuumize–polyurethane resin and curing agent— Casting— Curing — Open the mold and get the copies

Aluminum repod mold or mold steel repid mold

Use CNC, EDM, high-speed EDM and other equipment to fabricate metal and other hard metal materials such as aluminum or low carbon steel into molds

(the lifetime of molds can reach more than 10000 times).Product materials: ABS, PC, PP, POM, PMMA and other plastic materials. Please click our detailed rapid tooling service introduction

Surface Finishes

In order to achieve the effect of real products, Heran is able to do the following processes for customers: painting (glossy, matte, rubber oil painting, transparent oil, translucent oil,fluorescent

oil), silk screen printing, electroplating, anodic treatment,laser engraving, sand blasting, UV, bronzing, brushing, etc.

Congratulations for this successful project ! We also appreciate the good quality from heran, and above all the good contact & service from you ! Kind regards .

Jonas/Germany

First round sample looks very great thank you. We look forward to the mass production patrs soon .We will view it and get back to you soon. Regards,

Joseph/France

Wow, very nice! I know Heran CNC machining is avery professional aluminum parts builder, so I’m not really surprised to hear this! You build great tools!

James/USA