You can get full-services of injection molding here, no matter what materials and what colors. By using the finest injection molding machines from 55 to 1,350 tons with up to 32 cavities and finished part weights can range from 4 grams to 24 lbs. In addition, we also offer additional services including mold making, plastic surface finishing, assembly needs, etc.

Customer satisfaction is the goal for Heran, whatever the requirements and tolerances for your components are, we have the capabilities to meet your expectations.

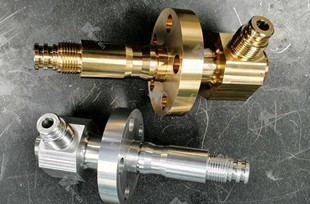

Tooling Materials

Before starting injection molding for low or high-volume production, high-tolerance CNC machined tooling is requisite. the materials used for CNC tooling are:

Tool Steel: Stainless Steel: P20, H13, S7, 718, 718H, 738, NAK80, S136, S136H,420,S7,1.2311,1.2312,1.2344,1.2343,1.2767 ,1.2085,1.1730,N690 ,M334,SKD11, SKD51.SKD61,

Other steel,316, 301, 303, 304, 420, NAK80, S136, 316Lect,other steel ,sus303,sus 304,ect other steel .

Aluminum: 6061, 5052, 7075 ,6082,ect ,Other Steel .

Plastic Materials& Additives and Fibers

With an extended range of plastic materials, you can choose what fits your needs perfectly.Each material has qualities that include heat resistance,

Impact strength, wear resistance, and many more.Impact resistant: ABS, PMMA, PVC, PE, PC ;Wear-resistant: POM, PEEK, UHMW ;Dimensional stability: PBT, ABS, HIPS, PPS ;

Chemical resistance: PEEK, PP, PBT, PA, PE, LDPE ;Rubber like: TPU, TPE, Silicon ;Cost-efficient: PP, HDPE, LDPE;Cosmetic: ABS, PC, HIPS

Additives and fibers to enhance the quality and esthetics of standard plastic materials. Glass fibers

The process increases the functionality and performance of the molded product. UV absorbers , Colorants,Flame retardants,Plasticizers

Surface Finishes of Injection Molding

The process includes various steps, from injection mold tooling to entire plastic injection molding. Surface finishes of molds are processes typically carried out during production.

At our company, we perform the specific surface treatment after the injection molding process according to customer requirements.Glossy ;

The SPI grade A1, A2, and A3 surface finishes are made with diamond buffing for a glossy and shiny surface finish;

Semi-glossy ; The SPI standard B1, B2, and B3 grade surface treatment uses grit sandpaper paper to yield a semi-glossy surface finish;

Matte ; The C1, C2, and C3 SPI grade surface treatments use grit sanding stones to achieve rough texture and uneven surface:

Textured ; D1, D2, and D3 grade treatments use dry blast glass beads, and oxides for the surface finish to produce a very coarse and textured surface.

Class of Injection Molding Mold

Heran is known for designing and manufacturing custom injection molds with top-grade materials. Our molding processes provide exceptional repeatability while ensuring rapid turnaround and affordability. We manufacture every plastic injection mold with precision to meet international standards. Whether it’s one-off projects, small batches, or production tooling, we do not compromise on the quality and reliability of mold tools.

Mold Class Purpose Shot Life Tolerance Lead Time

Class 105 Prototype Testing Under 5.000 ~10.000 shots ± 0.02mm 10-15 days

Class 104 Low-volume Production Under 100.000 shots ± 0.02mm 20-25 days

Class 103 Low-volume Production Under 500.000 shots ± 0.02mm 21-30 days

Class 102 Medium-volume Production Medium to high production ± 0.02mm 25-40 days

Class 101 High-volume Production Over 1,000,000 shots ± 0.02mm 25-45 days

From Rapid Prototyping to Production

Rapid Design Molds

Leverage our rapid design mold service to create efficient and accessible mold designs for your high-scaleproduction ,Our have a professional team with relevant expertise uses advanced technology to create mold designs that designs that exactly meet your final product specifications with less design complexity and production time, we offer cost-efficient molds that fit your requirements.

Injection Molding Prototypes

Revamp your product development process with our premium injection molding prototype tooling. Get easy design feedback and product validation from our experts. From small batches of molded parts to performing functional testing, our team provides fast manufacturing within days for market validation. Before full-scale production, Heran offers cost-effective aluminum tooling to reduce financial stress on you.

Production Tooling

Our production tooling is the perfect choice for a high-volume plastic parts production process. With highly durable tool steel material, you can rest assured that hundreds of thousands of parts will be manufactured with great results. Invest in the strength and quality of our superior molds, and see how they revolutionize your manufacturing process.

Gallery of Injection Molding Parts

Are still confused whether we can design and produce injection molded parts according to your specifications, get down to our gallery featuring our sophisticated design and production of various injection molded parts.

Congratulations for this successful project ! We also appreciate the good quality from heran, and above all the good contact & service from you ! Kind regards .

Jonas/Germany

First round sample looks very great thank you. We look forward to the mass production patrs soon .We will view it and get back to you soon. Regards,

Joseph/France

Wow, very nice! I know Heran CNC machining is avery professional aluminum parts builder, so I’m not really surprised to hear this! You build great tools!

James/USA