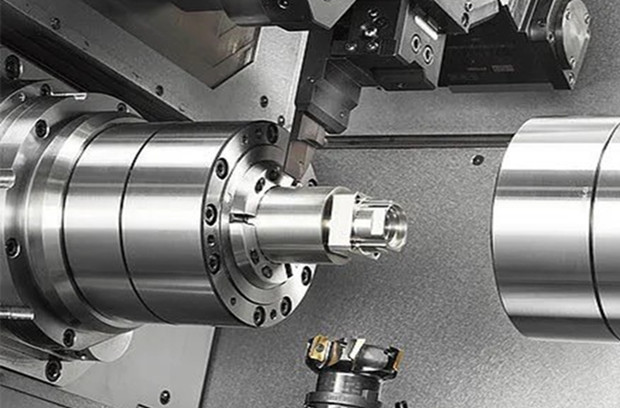

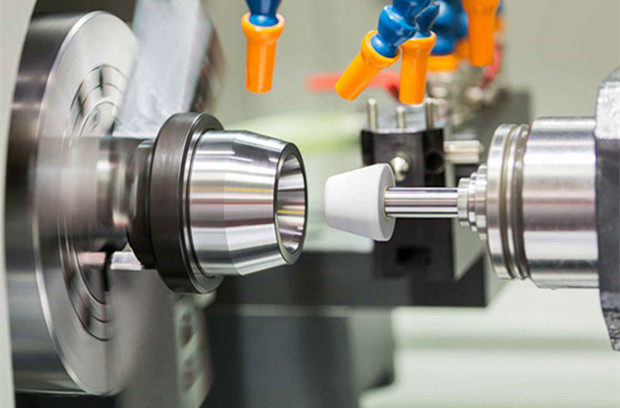

• CNC Turning Service

• CNC Milling Service

• CNC Drilling Service

• CNC Cutting Service

• CNC Grinding Service

• CNC Rapid prototyping

• Wire EDM Machining Services

Our Capabilities

• Tolerances down to 0.003-0.01 mm tight Tolerance • Pass certification ISO9001:2005. IATF16949

• All will be carry out 100% inspection for the entire process from project beginning until after-sale customer support .

How To Work With US

1, Upload your all info file online & tell us important details about your project to get an instant guaranteed quote.

2, Free Design for Manufacturability (DFM) analysis to suggest design improvements, finishes and processing techniques

that are best suited for your project and makeing sure the order and get into production step.

3, One-stop-shop service that ensures that parts remain consistent in their high-quality from start to end with excellent

finishes to convey aesthetics, ergonomics and protection.

4. Doorstep Delivery – Custom manufactured parts are shipped and delivered to your doorstep in as fast as 3 days.

5. After service feedback .

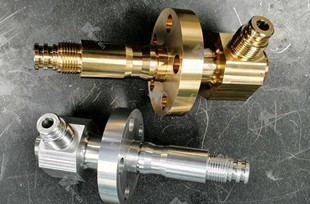

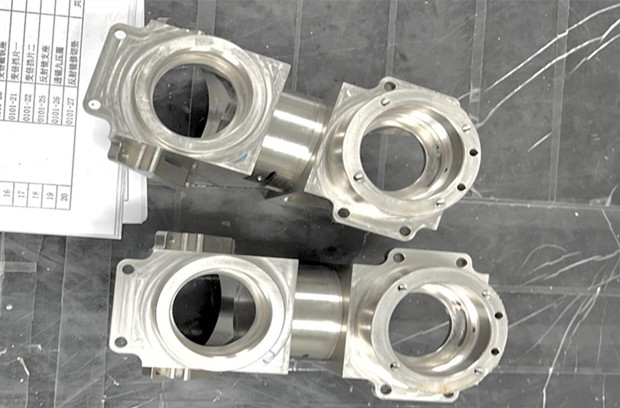

Gallery of CNC Machining Parts Show

Are still confused whether we can design until produce CNC Machining parts according to your specifications, get down to our gallery featuring our sophisticated design and

production of various CNC Machining parts.

Congratulations for this successful project ! We also appreciate the good quality from heran, and above all the good contact & service from you ! Kind regards .

Jonas/Germany

First round sample looks very great thank you. We look forward to the mass production patrs soon .We will view it and get back to you soon. Regards,

Joseph/France

Wow, very nice! I know Heran CNC machining is avery professional aluminum parts builder, so I’m not really surprised to hear this! You build great tools!

James/USA